By: Kris Thacker – Technical Sales Manager, Sumitomo (SHI) Demag

This year marks 100 years of innovation in the drive concept utilised across the entire Sumitomo Heavy Industries Group. A historical milestone, which commenced with the invention of the Cyclo® principle in 1925 by Lorenz Braren, continues to push the boundaries of processing precision, reliability and efficiency by the Group.

These developments have been fundamentally influential across manufacturing, particularly in demanding industrial applications, including robotics and injection moulding machines.

Nick Stockton, Technical Manager and Andy Pearce, Area Sales Manager at Sumitomo (SHI) Demag UK explore the evolution and performance characteristics of different drive variants. Including why the move to all-electric drives developed by Japan exclusively for the company’s injection moulding machines offers processors greater moulding precision and higher energy savings.

Powering the force transmission of the moulding process, there remain many different varieties of drive technologies in plastic manufacturing, highlights Nick. Despite incremental improvements in the performance of drives over the years, drive technologies can and do vary. Some offer faster speed acceleration and quicker braking. Others are more energy efficient.

Controlling the injection pressure and process optimisation is essential for mouldability. This precise motion control is what the drive does. Much like a gearbox, a drive transforms the rotational speed into a linear movement. The science is the same for all drives whether it is hybrid, variable frequency, electric servos, electric belt, direct drives or all-electric drives. The drive is quite literally the centrepiece of the injection moulding industry, asserts Nick.

In injection moulding, the choice of drive was previously application dependent. The requirements for sector and processing applications need to factor in so many varying aspects – including holding patterns, rapid changes in acceleration and deceleration, cooling times and component removal. Yet, the evolution of technologies now means that electric drives are increasingly viable for processing faster applications including caps and closures, as well as heavier loads such as automotive parts.

Andy expands: “Until recently, matching the motion force of hydraulics in larger tonnage machines was regarded as inconceivable. However, indicative of innovations in drive technology, ‘servo’ variants fusing all-electric direct drives with high-speed servo pumps now caters to the medium and high clamping force range, further enhancing energy-efficiency.”

Sumitomo (SHI) Demag is unique in that the company doesn’t use conventional motors in its injection moulding machines, highlights Andy. The reason – injection moulding isn’t a standard process. It is high speed with very fast acceleration and braking. Rather than incurring efficiency losses as a result of additional components used in conventional indirect technology, Sumitomo (SHI) Demag machine motors are directly linked to the axis. Resulting in a higher injection power and consequently a much more dynamic response.

Additionally, the in-house-developed electric drives are used in the company’s proprietary robot series SAM-C. This helps to optimise the robotic mechanics to match the fast-cycling dynamics, precision and efficiency of the company’s all-electric IntElect machines notes Andy.

Making powerful progress

One of the key processing advantages of electric drives is the ability to control the linear axis with velocities in excess of 500mm/s. These are typically managed by a closed loop control system located in either the machine controller (software) or the servo drive itself (hardware). The hardware solution offers a key performance advantage as the position control calculations are performed in real-time in the servo drive hardware. Resulting in the maximum performance.

Nick explains: “For industries where precision is paramount, the combination of electric drives and digital control turns injection moulding into a much more predictable and precise operation.”

Compared to hydraulic machines, electric direct drives only consume electricity when operational. In addition, kinetic braking energy can be recovered through recuperation technology.

The enhanced efficiency provided by electric direct drives results in significantly reduced energy consumption compared to hydraulic machines. For example, the IntElect and PAC-E series utilise between 40% and 85% less energy than their hydraulic predecessors.

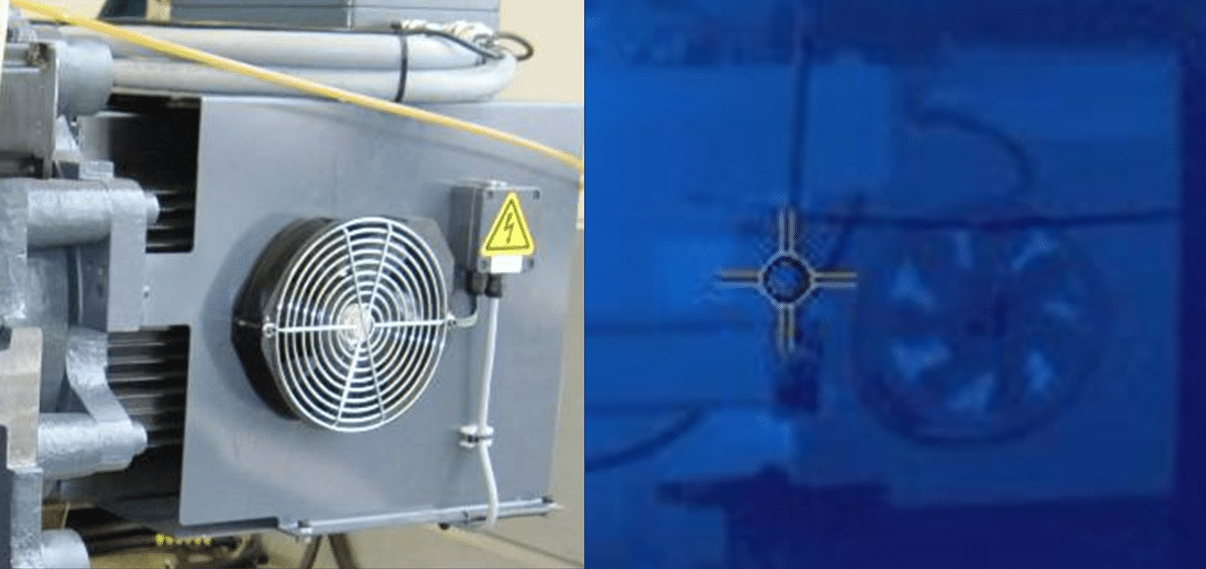

Heat transfer is also a factor to consider. Some electrical power is used to heat the barrel for resin melting, while another portion powers the machine drive, inverters, and motors, which also generate heat. All generated heat must be dissipated through thermal convection, or now more typically using an active cooling system.

Thermal imaging of the direct drive can also identify inefficiencies and heat emissions. On IntElect machines, the active air cooling system (fan) operates once the motor temperature reaches 55°C. If there is no heat emission from the drive, no additional energy is being used.

Another important factor when selecting drive size is the duty cycle, which refers to the proportion of operating time during which the motor is active versus idle or recovering. The implementation of active cooling can decrease the required recovery period, potentially enabling users to select a smaller motor.

Finally, replacing a drive system can represent a significant expense. Many moulding machine manufacturers procure their drives from external OEMs, which often complicates the process of sourcing replacement components or obtaining service support. This highlights the advantage of maintaining an in-house R&D centre focused exclusively on drive development for injection moulding applications.

Given that 95% of all new Sumitomo (SHI) Demag machines are now equipped with an all-electric drive, the company will continue to draw upon its extensive collective expertise and legacy to drive tomorrow’s future.

“As a part of the Sumitomo Heavy Industries Group, Sumitomo (SHI) Demag benefits from a powerful network of specialist companies, shared expertise, and close cross-company collaborations. This strong alliance allows the company to leverage technologies, innovations, and synergies across the entire group. Giving customers a more reliable and future-ready partner,” adds Head of Sales Ashlee Gough.