By: Kris Thacker – Technical Sales Manager, Sumitomo (SHI) Demag

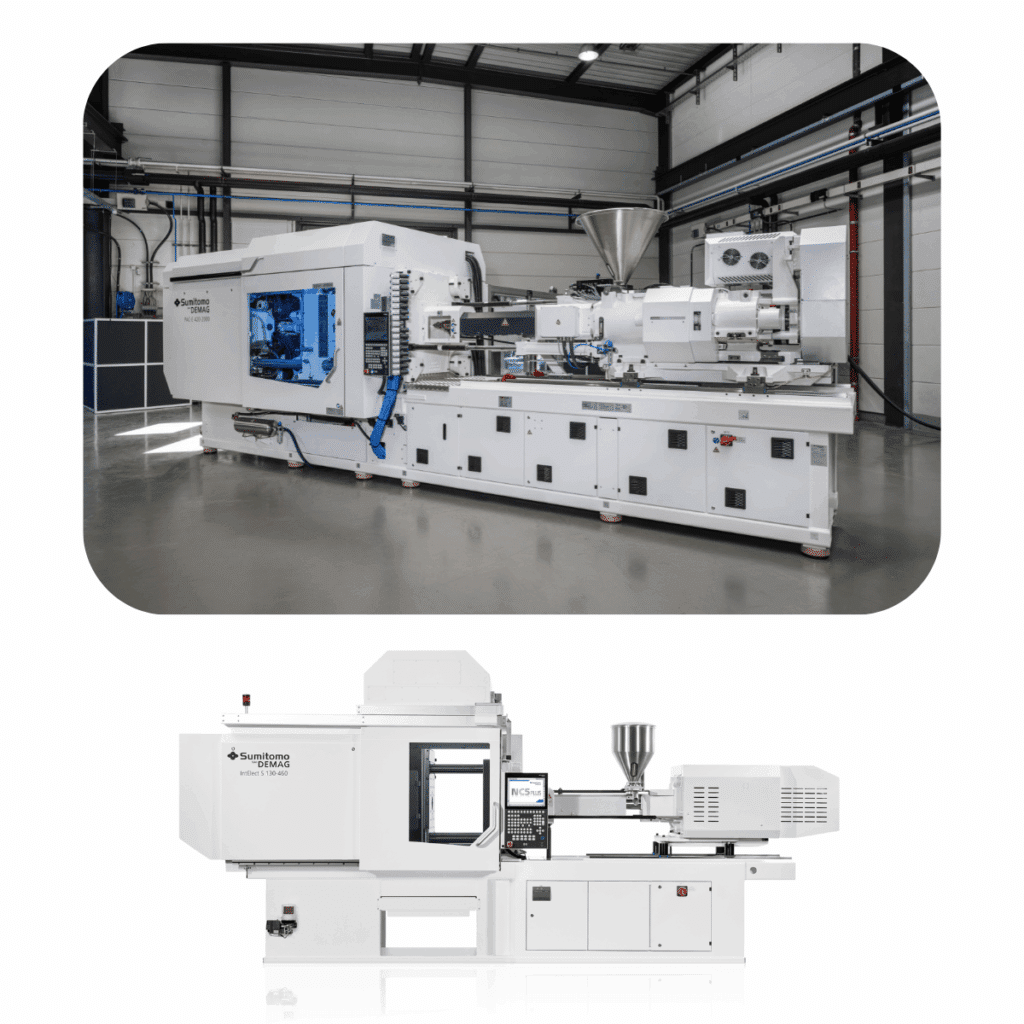

Sumitomo (SHI) Demag will demonstrate its comprehensive medical sector expertise across a range of applications at Plastics Live Ireland 2025, stand D7. The company’s extensive medical portfolio now includes IntElect cleanroom machines with a small footprint, IntElect LSR packages, the clean toggle PAC-E, and the proven fast-cycling hybrid El-Exis SP.

As a specialist in medical processing, Sumitomo (SHI) Demag will showcase scalable solutions designed to ensure consistent part quality while effectively reducing manufacturing costs per unit.

Exemplifying flexibility, cost and energy efficiency is the IntElect medical series. To maintain compliance with the explicit quality management and validation ISO 13485 standards for medical devices, all of the newest IntElect machines feature set user parameters. This helps to ensure that processes are kept within certain bandwidths and that users do not adjust pressure, temperature, flow and cooling settings without permission.

An all-electric solution for every medical application

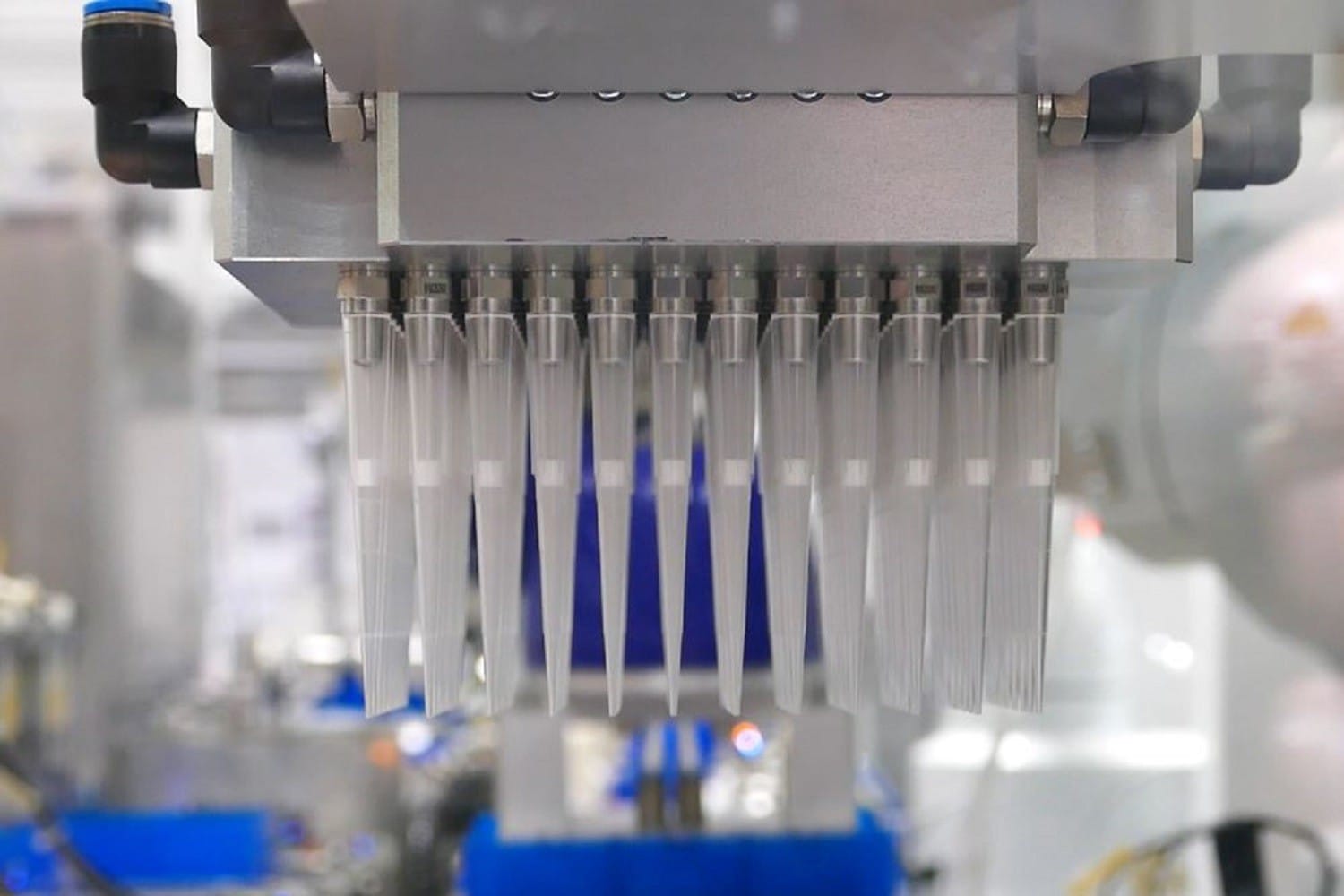

Responding to the most significant challenges for medical manufacturers, notably constant high output, rigorous technical requirements and high precision, the IntElect S medical series delivers the repeatability and accuracy required for highly demanding applications. Specifically, this machine is used to manufacture pipette tips, vials, drug delivery devices and pen-style injectors.

Visitors to K 2025 may have seen the IntElect S 130t demonstrating this precise control and high output. Presented at the Sepro booth, this exhibit produced 15 ml centrifuge tube caps using a 48-cavity tool, in a 10 second cycle time.

Another K show exhibit manufacturing medical valves and featuring the IntElect 130t LSR injection moulding machine appeared on the Nexus stand. Comprising intelligent robotics, precise slitting technology, optional camera inspection, and traceable packaging, this system represented the endless possibilities in 24-hour autonomous production.

In a complete cycle time of 40 seconds per shot, a 6 axis robot removed 16 moulded parts and transferred them to a slitting station. Holding them firmly in position for electric-driven slitting knives to make their cut, the next moulding cycle occurred concurrently, with the robot EOAT moving between the 16 cavity mould tool and slitting station.

Testament that the IntElect is not confined to small medical components, Sumitomo (SHI) Demag can also offer processors a 130 to 180 ton machine powered by a new 910 injection unit.

“One of the key benefits of being able to select a smaller footprint machine that can handle larger shot weights are the rapid energy savings. Built for high speed and precision, it is designed to handle extremely narrow tolerance medical applications produced in high volumes, yet give processors the flexibility to mould everything from small medical parts to larger components,” notes Ireland Sales Manager Kris Thacker. “

The future of advanced manufacturing efficiency

Redefining clean, energy-efficient injection moulding for the medical industry is the company’s latest 420t PAC-E machine. Drawing on the respective strengths and proven technology features of the El-Exis SP and IntElect machines, PAC-E sets a new three-second milestone for mass manufacturing hygienic healthcare applications ranging from medical cups to centrifuge blood collection tubes.

The clean toggle technology meets the strict hygiene demands stipulated in medical manufacturing, notes UK and Ireland Head of Sales Ashlee Gough. The latest 420t PAC-E machine pushes the limits in production with the fastest dry cycle time and an injection speed up to 550 mm/s. Additionally, its closed-loop lubrication system enables processors to support applications with high hygiene requirements including medical parts.

“PAC-E is engineered specifically to deliver peak sustained performance in hygienic, fast cycling applications. With its fast injection speeds and exceptional precision, the PAC-E enables flawless multi-cavity production, even for extremely thin-walled products,” explains Ashlee.

For processors where hygiene requirements are not as stringent, but cycle and injection speed is just as critical, the El-Exis SP still remains the uncontested fastest injection moulding machine in history. Capable of delivering a cycle time of less than two seconds, the hydraulic accumulator is the main reason behind the El-Exis SP’s short cycle times and injection speeds of 1,000 mm/s. As a result, processors can manufacture even thinner and lighter items, resulting in a significant reduction in raw material use, waste and shipping costs.

To see the company’s medical technology in action, Irish customers are invited to visit Sumitomo (SHI) Demag’s showroom in Limerick. The facility currently has two high-speed IntElect S medical-specification production cells (100t and 180t) running validations, tests and tool trials.

To book a visit and to find out more, visit Stand D7 at Plastics Live Ireland.